Glycolysis fermentation is key to making alcohol. It breaks down glucose molecules into ethanol and carbon dioxide, giving wine, beer, and spirits their alcohol content and flavor.

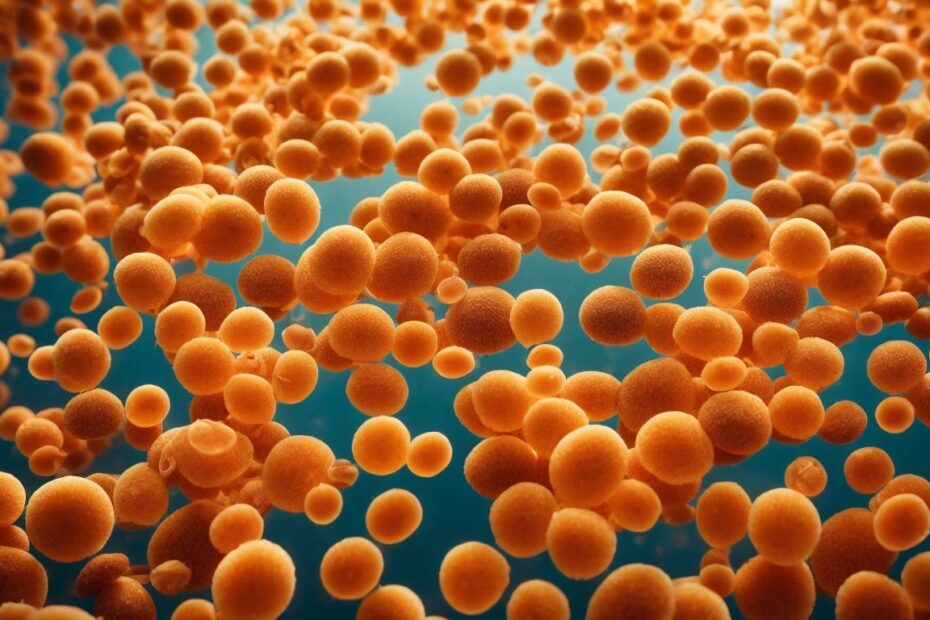

This metabolic process happens in yeast and bacteria when glucose is first converted into two molecules of pyruvate. Then, under anaerobic conditions, pyruvate is further metabolized to make ethanol and carbon dioxide.

Humans have used this process for thousands of years. Ancient civilizations fermented ingredients to make alcoholic beverages. Nowadays, breweries and distilleries use modern techniques and technologies to create a wide variety of drinks.

Alcohol production is a big industry. By understanding glycolysis fermentation, producers can optimize processes and make high-quality products.

Understanding Glycolysis Fermentation

Glycolysis Fermentation is a process that’s necessary to make alcohol. It changes glucose into pyruvate, which is further metabolized to make alcohol. This is important for industries like brewing and winemaking. Let’s look at the components and steps:

| Glycolysis Fermentation |

|---|

| Glucose uptake |

| ATP production |

| Phosphofructokinase activation |

| Pyruvate formation |

| Alcohol production |

In the first step, cells take up glucose. For this, they need energy in the form of ATP. The next step is to activate an enzyme called phosphofructokinase, which helps break down glucose further.

As glycolysis continues, it produces pyruvate. This then goes through different metabolic pathways, depending on the organism and conditions. In the case of alcohol production, pyruvate is converted to ethanol through fermentation.

Tip: To make lots of alcohol, optimize conditions like temperature, pH levels, and nutrient availability. Also, choose the right yeast and add the correct nutrients to get the best results.

Understanding glycolysis fermentation helps us understand how alcohol is made. With knowledge of this process and implementing the right conditions, industries can use it to produce alcoholic beverages.

The Role of Glycolysis Fermentation in Alcohol Production

Glycolysis fermentation is vital for alcohol production. It changes glucose into pyruvate, releasing energy and molecules for alcohol creation. Let’s explore how it helps with alcohol production.

We can view the role of glycolysis fermentation in alcohol production in the table:

| Stage | Description |

|---|---|

| Glycolysis | Glucose splits into two molecules of pyruvate. |

| ATP Production | Energy-rich ATP molecules form during glycolysis. |

| NADH Production | Glucose-to-pyruvate conversion creates NADH, an essential molecule for alcohol synthesis. |

| Alcohol Synthesis | Pyruvate undergoes further reactions to make various types of alcohols, such as ethanol or methanol. |

Glycolysis fermentation also regenerates NAD+, so the process runs smoothly.

Many years ago, people discovered they could make intoxicating drinks by fermenting certain fruits or grains. They’ve since developed their knowledge and techniques to optimize the process and get the same result every time.

In conclusion, glycolysis fermentation plays a big part in alcohol production. It creates energy-rich molecules and alcohols like ethanol or methanol. We can celebrate the amazing glycolysis fermentation!

Industrial Applications of Glycolysis Fermentation

Glycolysis fermentation has many uses in industry. These range from crafting alcoholic drinks to pharmaceuticals and biofuels. Let’s explore its industrial applications with some examples!

Industrial Applications of Glycolysis Fermentation:

| Alcoholic Beverages | Yeast breaks down sugars to make ethanol. This creates drinks like beer, wine and spirits. |

| Biofuel Production | Biomass can be converted to bioethanol or biodiesel. This is a renewable energy alternative to fossil fuels. |

| Pharmaceutical Industry | It manufactures antibiotics, vitamins and organic acids. This helps with healthcare advancements. |

The history of industrial applications of glycolysis fermentation goes back centuries. Ancient civilizations used fermentation processes to make mead and beer. Over time, technology has improved it.

Glycolysis fermentation has made a big difference in many sectors. From providing us with alcoholic drinks to eco-friendly fuel and medicines, it has an incredible impact on society.

Benefits and Limitations of Glycolysis Fermentation

Glycolysis fermentation has advantages and disadvantages. Let’s explore:

| Benefits | Disadvantages |

|---|---|

| 1. Produces alcohol as a by-product | 1. Less energy production than aerobic respiration |

| 2. Enables certain microorganisms to live without oxygen | 2. Makes toxic by-products like lactic acid |

| 3. Gives energy when oxygen is low | 3. Not very efficient for ATP production |

Also, glycolysis fermentation is crucial for making alcoholic drinks such as beer and wine.

Pro Tip: To get better end-product quality, you can control temperature and pH during fermentation.

Future Developments in Glycolysis Fermentation

Glycolysis fermentation is ever-changing, paving the way for exciting future advancements. Scientists and researchers are constantly on the lookout for new methods to boost this process, leading to enhancements in alcohol production and beyond.

Let’s discuss some of the most noteworthy areas where future developments in glycolysis fermentation are anticipated.

Researchers are focusing on increasing the efficiency of glycolysis fermentation. By optimizing parameters such as temperature, pH levels, and nutrient availability, it is expected that alcohol production will be significantly improved.

Moreover, genetic engineering techniques could enable custom modifications to microorganisms involved in the fermentation process, thus boosting yields.

Advanced bioreactor designs are also receiving attention. Innovations such as microfluidic devices and continuous flow reactors offer more precise control over reaction conditions while improving scalability.

These novel designs not only contribute to higher alcohol production rates but also allow for more flexibility when it comes to optimizing processes.

Exploring alternative feedstocks is a key aspect of future development in glycolysis fermentation. Currently, most ethanol production depends heavily on corn or sugarcane, raising worries about food security and agricultural sustainability.

Therefore, researchers are researching the utilization of non-food biomass and waste materials as carbon sources for alcohol production. This transition to sustainable feedstocks has the potential to revolutionize glycolysis fermentation practices.

As we explore the possibilities of future developments in glycolysis fermentation, we must remember its long history. Glycolysis dates back centuries, when yeast-based fermentation was used to create alcoholic drinks like beer and wine.

Over time, scientific discoveries added to our knowledge of this natural process, such as Louis Pasteur’s realization of yeast as an important component for alcohol formation. These historical milestones have served as stepping stones towards modern-day innovations.

Conclusion

Glycolysis fermentation is complex. It converts glucose into ethanol and energy-rich molecules. This dual capability is essential for organisms, like yeasts used in the brewing industry. We can trace this process back thousands of years!

Humans discovered the art of fermenting grains to make alcohol. Since then, advancements in science and technology have enabled more controlled production methods. Glycolysis fermentation is still key in winemaking, brewing, and biofuel production.

Understanding its intricacies unlocks the potential for creating alcoholic beverages. With careful manipulation of environmental conditions and yeast strains, brewers control the final product’s flavor, alcohol content, and more.

Frequently Asked Questions

1. What is glycolysis fermentation?

Glycolysis fermentation is a metabolic process that converts sugar into alcohol, such as ethanol. It is a key step in the production of alcoholic beverages.

2. How does glycolysis fermentation work?

Glycolysis fermentation begins with the breakdown of glucose into two molecules of pyruvate. The pyruvate is then converted into ethanol and carbon dioxide through a series of enzymatic reactions.

3. What are the main products of glycolysis fermentation?

The main products of glycolysis fermentation are ethanol and carbon dioxide. These are responsible for the characteristic flavors and effervescence in alcoholic beverages.

4. What types of organisms use glycolysis and fermentation?

Glycolysis fermentation is commonly used by yeast and some bacteria to obtain energy in the absence of oxygen. This allows these organisms to survive and thrive in environments where oxygen is limited.

5. How is glycolysis fermentation used in alcohol production?

In alcohol production, glycolysis fermentation is utilized to convert sugars from grains, fruits, or other sources into alcohol. This process is carefully controlled to achieve the desired flavors and alcohol content.

6. Are there any health benefits or risks associated with glycolysis fermentation?

While moderate alcohol consumption has been associated with certain health benefits, excessive alcohol consumption can have negative effects on health. It is important to consume alcohol responsibly and in moderation.